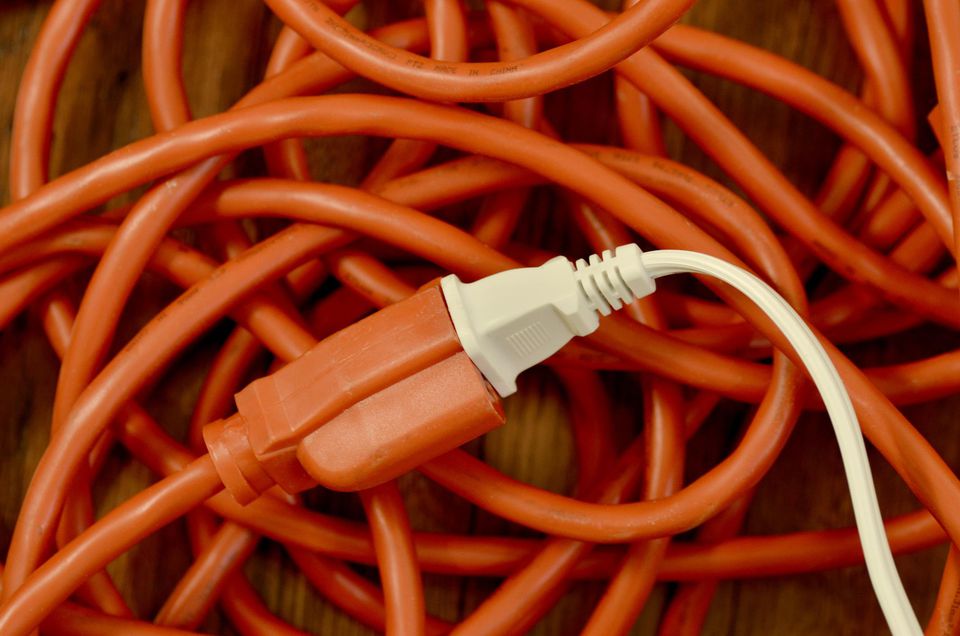

5 Simple Extension Cord Rules to Improve Work Site Safety

An extension cord comes in handy no matter where you're working. Most worksites have a few running at any time of the day and in almost every area of the office or site. It is why that's so important to pay close attention to a few necessary safety precautions. Overlooking these five simple extension cord rules to improve worksite safety can turn this overlooked must-have into a hazard in waiting. Let's take a closer look at how you can keep yourself safe and in compliance with OSHA standards.

Basic OSHA safety compliance

The primary way of making sure that a work or construction site complies with OSHA's regulations is to use one of two approaches. An Assured Equipment Grounding Conductor Program is an option. It requires the daily inspection of every point. Despite just how effective this can be, most users ignore the regular inspection. It leads to dangerously disregarded power points and extensions, which are often severely neglected by the time inspection is eventually done. Unless rigid management techniques keep apparent oversight over an AEGCP, an alternate approach is available. Ground Fault Circuit Interrupters monitor the power put out from a plug, and the returning power. If there's a difference, this indicates a leak and the power cuts off. This approach is the most reliable due to the way that the potentially hazardous situation resolves immediately.

100-foot extension cord maximum length

The maximum length of an extension cord is set at 100-feet by OSHA standards. Any worksite that needs a longer extension must put a temporary power distribution box in place. 100-foot extension cords are ideal for both continuous use equipment like running power from a generator or powering a compressor. Never use an extension cord unsuited to the amperage of the equipment you're powering. Also, don’t forget that 220/240V tools will need a 220 extension cord. There are three basic types of extension cords you’ll find - light-duty, medium-duty, and heavy-duty.

Light-duty extension cords

Light-duty extension cords are very thin and are for extremely light-duty equipment. They're are not meant for use with any heat-generating appliances. Most light-duty extension cords do not come with a grounding wire. Consider an extension cord with the switch when you'll be using it for light appliances like clocks, small desk lamps, and chargers. Don't use devices exceeding seven amps on a light-duty extension cord. 25-feet light-duty cables typically come at 18 AWG. 50-foot cords at 16-AWG, and 100-foot cords at 14 AWG. AWG stands for American wire gauge which is a reflection of the diameter of the cable

Medium-duty extension cords

Medium-duty extension cords are of medium thickness and are for powering grounded appliances. There is also the third grounding wire. It's the most common type of extension cord that's used to run televisions, computers and other devices pulling under 10-amps. The safety guidelines for a 25-foot medium-duty extension cable recommend a 16 AWG wire. At 50-foot go for 14 AWG, and at 100-foot 12 gauge extension cord is the safest.

Heavy - duty extension cords

A heavy-duty ten gauge extension cord is the thickest that you find, granting the best sheath & insulation. It also makes them the most heat resistant and the most rigid. A heavy-duty extension cord powers appliances such as heating devices and tools which draw between 10 and 15 amps of power. Always pick an extension that gives you as close to the exact distance as you need. You don't want any longer due to the voltage drop. The best you can get is a 100-foot 30 amp extension cord.

Don't plug one extension cord into another

Power cords have power ratings for a reason. When you couple two identical cords, it cuts the capacity that each lead can carry in half. Irregular fluctuations in voltage occur, and overheating follows. Two unequal extension cords raise the risk of overheating and malfunctioning even more. Extending an extension cord without using a temporary power distribution box is a direct violation of OSHA standards. This can potentially lead to fire, electrocution, or the failure of connected equipment. Run one appliance per extension cord only. The exception is for small appliances such as cell phone chargers, and other low-voltage equipment.

Inspect all extension cords

Using an extension cord with any sheath damage is a violation of OSHA standards. Even though an extension cord continues functioning, the sheath damage allows current to leak, which leads to irregular fluctuation in voltage and potentially overheating if there are extensive damage and multiple power leaks. Insulation tape is not a good enough quick fix for worksite safety. Rather discontinue use and wait on a replacement. Upon your inspection, check for:

- Any signs of cord damage

- A mark indicating independent laboratory testing (e.g. UL, ETL, CSA)

- Ensure that each plug is securely inserted into it's an outlet.

- Extension cords plugged in that aren't in use (unplug and pack away)

- Any cable contact with water

- Complete coverage of any area of the cord

- Overloaded NEMA 5-15R outlets and extension cords

Environmental considerations for extensions

Long extension cords cannot run through water or snow. They must also not come into direct contact with the ground. Always avoid allowing anything to cover your cords. Even if you are running a flat extension cord, it must not be covered. Without allowing the heat to escape, you're setting up a fire hazard. This is why it is a violation of OSHA regulations to run a temporary extension cord through a wall, within a door, in a ceiling or beneath a floor. Indoor cables are for indoor use. Outdoor cables can generate a lot of heat and are far more rigid due to the heavy-duty insulation. Don't misuse either type.

Maintain basic extension cord safety every day

Remember, an extension cord is something that's for temporary use. Just because a heavy-duty 20 amp extension cord looks durable, you don't want to be running one permanently. The cord's capability to carry current degrades over time, and when you use the same wire every single day, this can quickly lead to electrical issues. From fluctuations resulting in power spikes to the outright danger of having a hot cable that's ready to ignite, don't suffer the risk of shoddy cables. Instead, employ these simple rules to keep track of your worksite safety without any worries. Regular inspections will go a long way towards giving everyone complete safety and granting management peace of mind.